Processes can be blamed or praised for the outputs they produce.

A process that is applied in exactly the same way, time after time, will consistently produce the same output. This is a stable process.

A stable process can produce an undesirable. We call an output that is not desired non-quality.

As the process is stable you can correctly assume that the process is causing the non-quality output. To change the process to produce quality output we must first find the root cause somewhere in the process, that is causing the non-quality output.

In a company all work is a process whether it is decision-making, manufacturing widgets, writing code, inputting data, making sales calls or compiling a book of accounts. The superpower of processes is that they control the outputs which constitute the results that the company is getting.

A perfect process

Simply put, a process is a series of steps designed to produce an output. Each step in a process is, in itself, a process.

A process uses resources such as time, materials, equipment, tools, overhead requirements, personnel and consumables. Collectively this is the cost of the process.

Each step in a process either contributes, or does not contribute, to ensuring the output desired is achieved. A step that contributes to the output is a value-added step. A step that does not contribute to the output is a non-value-added step.

In all processes something is moving through the steps. For example in a process of auto assembly the various parts that make up the vehicle are moving through. In a supplier payment process, information is moving through the process resulting in the transfer of funds to the supplier. In surgery body parts are moving through the process being removed, partly removed or repaired. Surgery might also include parts moving through – new heart, metal parts or manufactured valves.

Various types of waste can be found in processes. Time can be wasted when a part is sitting with no value-adding activity. Materials can be wasted by being rejected for non-quality or off cuts. Non-value-added steps might exist that are seen as necessary. Repetitive inputting of data in a systems based process is waste. Rework is was found in almost all processes.

Cycle time is the time it takes from step one in a process until the process is completed. This is an end-to-end time measure. The time taken to do the actual work is called touch time. Touch time starts when an individual step in the process has begun and includes any ‘hands on’ activity during that step, and stops when the step is complete. A golf game is a useful metaphor to explain the difference between cycle time and touch time. Touch time in a golf game occurs when the ball is hit towards the hole in the green. A single stroke or putt usually takes less than three seconds. A professional golfer might regularly take 70 strokes to complete sinking the ball into all 18 holes. In a golf game, that is 210 seconds or 3.5 minutes. In practice a golf game takes anywhere between 4 to 6 hours to play. In this metaphor cycle time is 4 to 6 hours while touch time is 3 ½ minutes.

Another simple example might be brushing your teeth. The touch time is the time that the brush is actually moving across your teeth whilst cycle time will include opening the toothpaste tube, wetting the toothbrush, moving it to your mouth, brushing your teeth, spitting, rinsing your mouth, cleaning the toothbrush, placing the cap back on the toothpaste tube and and returning the toothbrush and tube to its place on your vanity.

With these understandings of the elements of a process we can define a perfect process:

A perfect process has value-adding steps only, is devoid of waste, consistently delivers quality output, cycle time is equal to the sum of touch times and resource use is as low as it can go.

Process Improvement

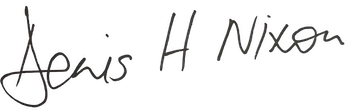

The chart above indicates the various transformation phases in redesigning a process from unstable to near perfect. We use the term ’near perfect’ because every process has some area which can be improved.

An unstable process which is one that gives inconsistent outputs must first be stabilized so that it produces the same output every time.

It is possible that the output of the stable process is non-quality. Nonetheless, it is a ‘good’ process in that the process itself is producing the same non-quality output every time. It is designed to do that.

If a stable process produces quality output we called this a ‘capable’ process, for it is capable of consistently producing quality outputs.

A capable process might have unnecessary steps. Simplifying a process often leads to a reduction of 30% or more in work. This is a simplified process. During simplification wastes of different types are detected and contribute, once remedied, to the reduction in the number of steps or touch time work duration.

Throughput is the rate at which an output is generated. Throughput is always determined by the longest step in a process. If we consider water flowing through a garden hose and we wish to increase the rate of flow, we might open the tap more fully thus increasing the pressure which will increase throughput. alternately a kink in the hose can be straightened or the sprinkler attached to the end of the hose opened more fully. If the constraint was the degree to which the tap was open then opening the tap would increase the throughput. If the tap was fully open but there was one or more kinks in the hose, straightening those would increase the throughput. However if the tap was fully open and there were no kinks in the hose then the aperture of the sprinkler on the end of the hose would be the constraint. Every process has a constraint to throughput and dissolving that constraint will increase throughput. Once the constraint has been dissolved in the hose the final constraint will be the diameter of the hose. To increase the throughput will require replacing the hose.

Final Note

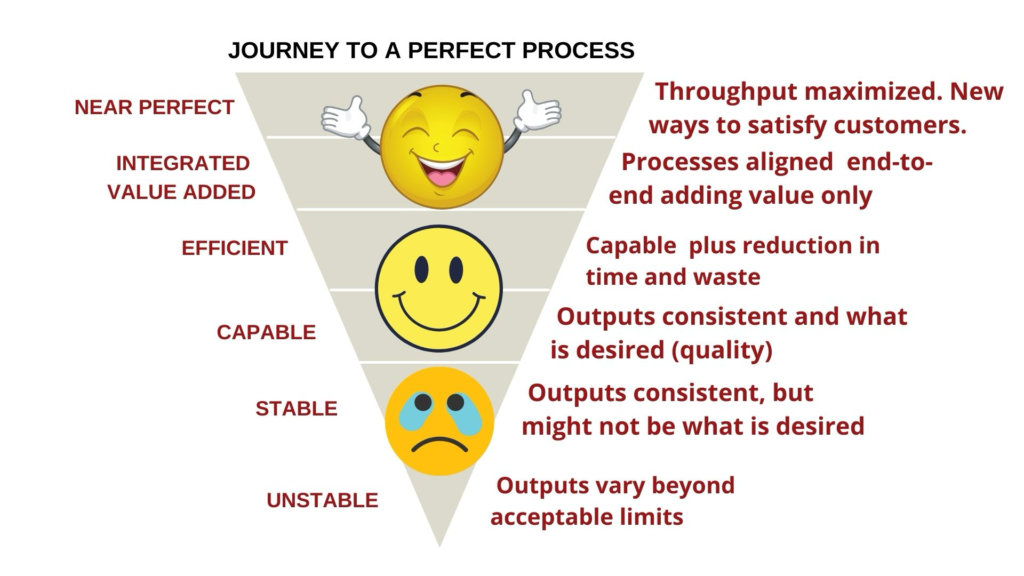

Process design and discipline accounts for 80% of customer satisfaction. The human factor comes in at four levels:

- Following the processes

- Applying skills in touch time

- Putting customer first in their interactions

- Going the extra mile

BUT without processes that satisfy customers the human factors are of wasted on recovering only.