Over the last 20 years there has been a growing interest in process redesign. 5S, A3, Lean, Agile, TQM, TOC, PDCA, DMAIC, Six Sigma and its multicolored belts, SMED, Kaizen, Kata and Gemba — are some of the many aspects of process redesign that have come into companies’ lives.

As process thinking has been reduced to pieces in this reductionist approach the System view has remained mainly unattended. This reductionist view has been driven by consultants who have packaged elements of process thinking and branded them, promoted them through books, lectures, consulting and coaching. That this work has had an impact on performance for the good, is unquestionable, especially in the manufacturing and assembly businesses.

Reducing the process system to pieces piggybacks on another reductionist effort – that of organizing companies into functions and departments. Together these two efforts prevent the company to be led and managed as a system. What has got lost in this reductionist view of organizations and processes is leading and managing the system that makes up the daily life of corporations. Today corporations are working with thousands of processes that look more like the noodles in a bowl of spaghetti than an aligned, interconnected system to achieve sustainable growth.

The human body is made up of millions of processes which are integrated and intertwined and whose outcomes result in health or disease, vitality or listlessness. But the body itself is part of a much greater system in which we all live. The air we breathe, the water we drink, the food we introduce into our bodies, the poisons we absorb through our skin, through cigarette smoking, through alcohol drinking and through multiple chemicals in highly processed food, all are part of the system in which our bodies have their existence. Our bodies are also bombarded by sounds, images, words written and spoken, weather conditions, social interactions, viruses, bacteria and germs. It is a huge system that our body finds itself in.

In a similar way processes in companies are in an environment consisting of policies, KPI’s, strategies, resources, advisors, managers, customers, shareholders, technology, regulations, competition and employees to name a few. The most difficult part of processes is that they exist in organizational departments and often are not recognized as part of a greater system. End-to-end processes, those that start with a customer need and end with a (hopefully) satisfied customer, cross multiple departments and functions with many handoffs and rework and errors.

What is Process Thinking?

I asked Perplexity (an AI application) what process thinking is and the answer stuck to the reductionist view of a process as being made up of steps and outcomes and able to be improved.

Process thinking sees processes as a system of integrated actions responding to the system in which the company exists. Process thinking, in a business, sees that all results are produced by the spaghetti bowl of processes. If the results are not as desired then there is a problem in the system of processes for they must be designed and interconnected in such a way as to produce the results desired by the whole company. These desired results are reflected in the constant progress towards achieving its mission and vision sustainably, and, being capable to take advantage of the large system in which the company exists.

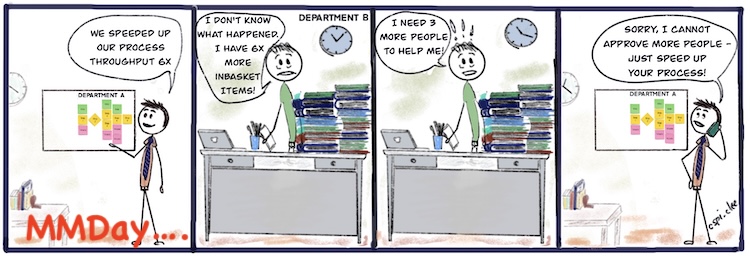

Systems Thinking, generally, often deals with unexpected consequences. In process thinking, this same systems thinking comes into play. A Marketing department might develop an effective marketing campaign, the success of which, causes a backlog in production because the manufacturing process is not capable of handling the increased demand. Or a decision to standardize often used components or designs by engineering leaves warehouses filled with non-standard materials to be written off. Or, a standard cycle time for a department’s work is out of sync with what the customer expects. Many companies have introduced new products to increase revenue which involve entering a new market for which they do not have the capability of serving and the product fails.

Two examples:

Samsung Galaxy Note. This iPAd like product suffered from having batteries that caught fire. What was discovered was a lack of capability in testing and QA. Their processes for testing were not effective in ensuring safe batteries. Discontinued in 2020.

HP TouchPad

The touchpad had a confusing operating system and poor app support showing that HP did not have the capability (spaghetti of processes) needed to compete in the tablet market successfully. It discontinued the use of the OS, 49 days after launch.

CAPABILITY

A company is capable if they have the capacity and ability to do something effectively. To compete with iPad a company will need the capability to design, to develop software, to market, to develop or acquire apps and produce at a cost that allows a good margin. Also, capability to source suppliers, design cost effective and reliable logistics, support customers, distribute sales. And these capabilities must equal or exceed Apple’s capabilities.

Process Thinking will cause leaders to ask of a strategy: ‘Do we have the processes that are capable of delivering on the related strategic objectives?’. In reality, companies often ‘throw the objective over the wall’ to be caught by middle managers who must develop a plan to implement the changes needed and achieve the objectives. Process Thinking will cause the processes needed to achieve the objectives to be examined and if the capability is found to be lacking, the processes will need redesigning to be capable to deliver on the objectives.

An example

Many companies grapple with complaints from suppliers regarding payments being late. Unhappy suppliers will often pad their pricing to allow for late payments, others might not renew contracts, still others might drop their focus for quality service. A reputation as a ‘good payer’ will be important in a company that finds competing for suppliers to be a challenge.

There are quite a few functions and departments involved in making payments to suppliers.

The client sends an invoice, the recipient of the product or service from the supplier verifies that the work is done or the goods delivered, the necessary paperwork and invoice is scanned and encoded into the computer system which automatically advises accounting of the payment request, accounting work through the list of requests to QA the completeness of the encoded data and scanned documents. If accounting rejects the request for payment for errors or incompleteness an email will be sent to the requester to start again or provide information. Once passed QA the request is then routed for approval by the designated signatories and on completion forwarded to finance, who prepare the payment request for Treasury. Treasury ensure the funds are available by moving funds around and then request the bank to prepare a check and advise the customer to collect it. Each step in the process is in a different department and each has its standard time for completing the task.

| Step | Standard in days | Running time in days |

| Client sends invoice | 1 | |

| Invoice checked for work completed or goods received | 3 – 8 days depending on the nature of the billing | 4- 9 |

| Encoded to system | 3 days | 7 – 12 |

| Accounting QA | 6 days | 13 – 18 |

| Approvals | 7 days | 20 – 25 |

| Finance | 3 days | 23 – 28 |

| Treasury | 7 days | 30 – 35 |

NOTE: The above is actual standards in a real company whose commitment to suppliers is 28 days for payment.

If QA rejects, then the time will be greater. Standards are not always met. This company paid on time just 40% of the time.

Process Thinking requires that the thinker sees the big system picture and not just the part of the process for which they are responsible. Payments are often more complicated. For example, in contracting, a site visit by the Project Manager to confirm work done for progress payments may take a week. A warehouse might be backlogged on encoded delivered goods. Holidays might interfere with the lapsed time. Treasury might have specific days e.g. Friday when they submit payment requests to the bank. This can add several days. Audit might require original hardcopy of invoices be kept by the company. There might be delays in receiving these. All part of the system.

PROCESSES THEMSELVES

There are at least 20 aspects of processes that a Process Thinker takes into consideration. Here are just a few:

- Throughput is the rate (#per hour for example) at which a product is produced or a service completed. Throughput is dictated by the longest step in the process, called the constraint. To increase throughput the constraint needs to be dissolved.

- Value adding is when a step, in the process, done once, changes what is being worked on to what the customer wants and is willing to pay for (values).

- Rework. If something needs to be reworked (correcting errors, non-quality outcome, information missing) the cost and effort of the rework is waste. The company paid for something, but it was not delivered, causing more expense.

- Waste. There are multiple types of waste (Google this or ask Perplexity). The essence of waste is ‘unnecessary’. Unnecessary time spent, unnecessary waiting before processing, unnecessary purchasing of quantities of materials ( a thought – a good warehouse is an empty one through which goods pass but do not reside), too many steps, unnecessary signatures, excess screens for a transaction and so on.

- Phases of process effectiveness. Processes are perfect when it produces the outcomes desired, with throughput matched to demand, without rework and in which all work is added value (no waste). I call this a near-perfect process because there is always an opportunity for improvement.

- Phase 1 – process is stable and produces same result every time – whether good or bad. Phase 2 – capable: Outcome is quality always. Phase 3 – Efficient: value added steps only, little waste and WIP. Phase 4 – Simple: Process has the least amount of work possible to produce outcomes and is flexible to throughput requirements. Phase 4: Near perfect: only individual value adding actions can be improved.

- Carbon footprint. The amount of C02 that is produced by a process beginning with raw source of materials to output completed and delivered. AI with its huge server farms have a large carbon footprint.

- IT Systems. IT systems (hardware and software in this article) are processes with automated workflows, embedded QA’s, decision-making and communication capabilities.

Next Article: Process Thinking and strategic development and implementation. The driver of the old company System is dependent on its vision and mission and the strategy or strategies to achieve them. In companies today strategy, IT and operations need to work as one to achieve their objectives.